Extrusion Machines

Milacron both designs and builds full extrusion systems in-house, maintaining complete control of your precise equipment needs. From extruders to new and rebuilt extrusion barrels and screws, to pipe heads, dies, and downstream equipment, you get powerful, reliable solutions that meet your unique needs. Milacron’s demonstration and development laboratories have made a science of optimizing processing via natural compression. This creates a highly customizable approach for our customers: one that increases productivity, output, and accuracy while reducing costs.

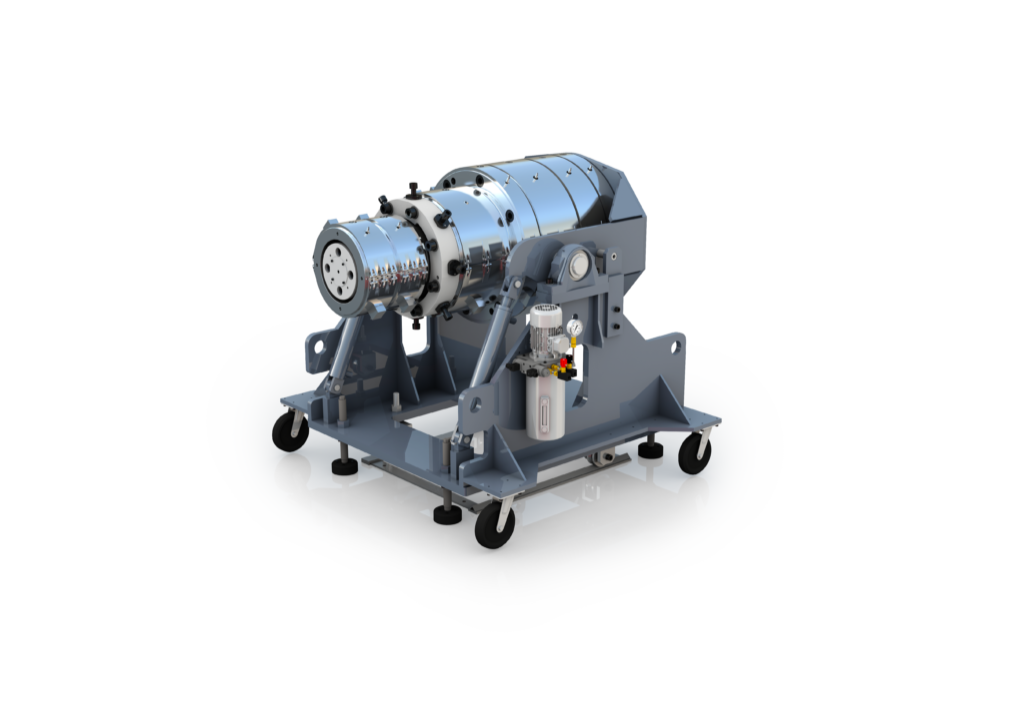

Twin Conical (TC)

Milacron's conical TC twin screw system offers a range of options for every application requirement:

- Custom screw designs that are individually tailored to the requirements of customer processes for optimal performance.

- Feeding systems that meet the requirements for process performance: hopper feeding, volumetric or gravimetric dosing for one or more components

- Options for regulating the temperature of the screw core.

- Cylinder cooling system: water, HTF, air

- A variety of drive and motor systems available, including AC vector motors, brushless and normal DC motors.

- Advanced manufacturing materials, including tungsten-coated screws and tungsten-plated cylinders, for maximum wear protection and low life cycle costs.

Twin Parallel (TP)

Milacron’s TP Series of Parallel Twin Screw Extruders is designed for greater output, superior performance and higher profits.

- The strongest and most reliable gear box available on the market today.

- Ideal for heat and shear sensitive materials.

- High surface area, low shear screw designs for efficient heat transfer.

- Positive displacement pumping characteristics.

- Narrow residence time produces optimal melt condition

Single Screw

Milacron PAK Series of Single Screw Extruder Systems gives all the advantages for productive operation.

- Standard AC motor & drive package.

- Double reduction gear reducer with heavy duty integral roller thrust bearing for extended life.

- Large cast-in water jacket in feed throat for efficient cooling.

- Bimetallic barrel with rupture disc for long life.

- 4-Bolt swing gate for faster die changeover.

- Standard discrete control package or optional Mosaic microprocessor control.

- Analog melt temperature and melt pressure indication.

- Production Smooth Bore (PAK) models available from 2.0″ up to 10″ or larger.

- Floor Mounted (S-PAK) or Pedestal Mounted (S-PAK-T) Coextruder models available from 3/4″ through 1-3/4″.

- Grooved Feed (G-PAK) extruders available from 45mm through 150mm.

Die Heads

Milacron just released a new die head designed for the production of PVC pipes. The MPH die head replaces the PH die head series to increase performance to win in today’s market.

- Higher output capabilities

- Reduced product change over times

- Improved wall control