About Us

Ferromatik was founded in 1956 in Malterdingen near Freiburg, Germany, and has been part of Milacron, headquartered in Cincinnati, Ohio, USA, since 1993. Ferromatik is considered a pioneer in multi-component technology and was the first European manufacturer of an all-electric injection molding machine in the early 1990s. With over 65 years of experience, Ferromatik Milacron today offers a comprehensive product portfolio of Milacron all-electric and servo-hydraulic injection molding machines, as well as comprehensive support, service and machine maintenance including the supply of original spare parts and components.

The team can deliver the entire spectrum of services that the plastics industry can offer. Expertise covers injection, co-injection, extrusion, low-pressure injection molding, process control, and life-cycle management. We thrive on solving problems and equipping our customers with new competitive advantages and superior products.

SUSTAINABILITY

As a global industrial company, we are committed to pursuing a leadership role and fulfilling our duty to improve the social and environmental impacts of our activities. Our strategy includes adopting policies that advance Hillenbrand's support of the environment and human rights of the people who live in it.

PRODUCTS & SYSTEMS

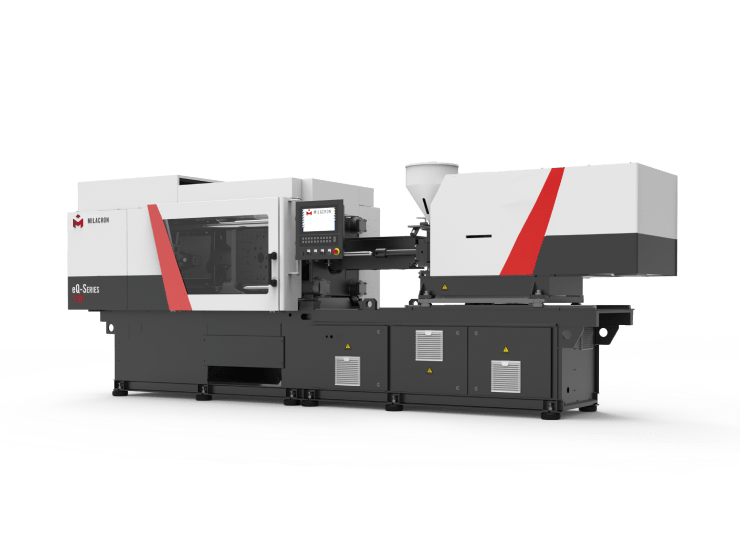

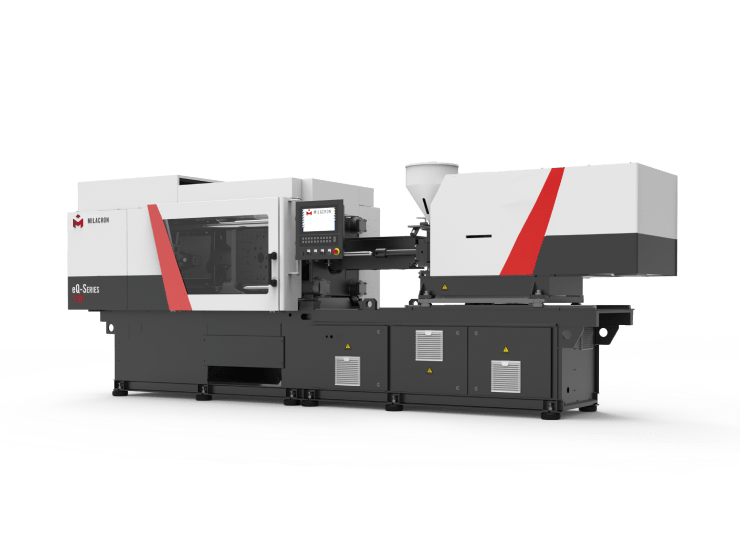

Injection Machines

From 6 to 6,000 ton clamp capacities, Milacron offers you the widest range of injection molding machines. Choose from servo or hydraulic machines with a full range of plastics processing technologies, including multi-component and co-injection.

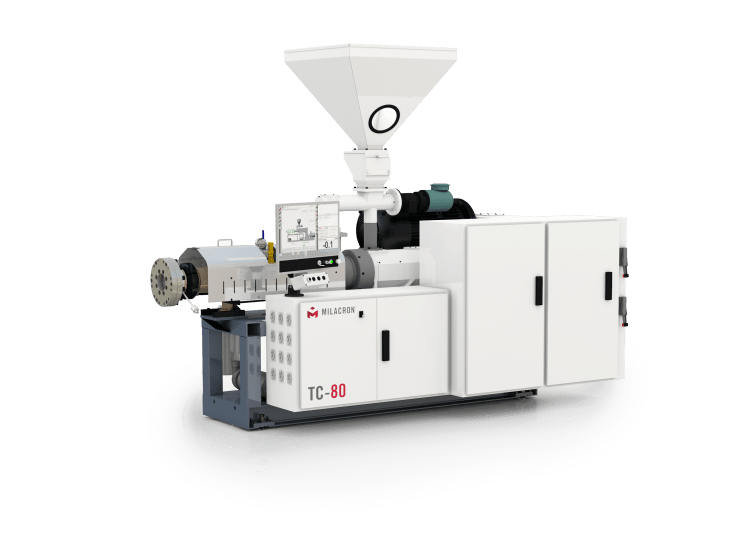

Extrusion Machines

Milacron both designs and builds full extrusion systems in-house, maintaining complete control of your precise equipment needs. From extruders to new and rebuilt extrusion barrels and screws, to pipe heads, dies, and downstream equipment, you get powerful, reliable solutions that meet your unique needs. Milacron’s demonstration and development laboratories have made a science of optimizing processing via natural compression. This creates a highly customizable approach for our customers: one that increases productivity, output, and accuracy while reducing costs.

Auxiliary Systems

Milacron is the leading supplier of plastic processing auxiliary equipment. Our plastic auxiliary equipment consists of several complementary components, such as material management, quick mold changes, reclamation, heat transfer, robots and conveyors

PROCESSING TECHNOLOGIES

MonoSandWich

The MonoSandWich (MSW) Technology developed by Milacron, is a simpler version of Multi-Component technology. It is designed to significantly reduce manufacturing costs as compared to conventional sandwich molding technologies.

iMFLUX

What if you could…

- Run various MFI materials with no operator touches

- Visually see your energy and operational savings in real-time

- Improve uptime and quality across your site

- Remove the challenges of start-up, saving time and scrap

See how at K-2022.

iMFLUX and Milacron will partner together at K-2022 to demonstrate the iMFLUX low constant pressure technology on the Milacron eQ series press. We will process various MFI materials, including 100% PCR, with no operator touches, will show how iMFLUX can reduce or eliminate common mold start-up challenges, and will allow you to visually see energy and operational savings in real-time via the Milacron M-Powered system. During the demonstrations, visitors will be able to create a custom crinkle bag from a selection of resins with highly variable viscosities, and various colorant options.

Demonstrations will take place at 12pm, 2pm, and 4pm daily at the Milacron booth #14/B31. Additional information is also available at the iMFLUX booth #15/D23.

For more information on the iMFLUX technology visit www.imflux.com

Bolt-On Injection Unit

The bolt-on injection unit is suitable for almost all applications. The injection and plasticizing movements of the self-contained injection unit are controlled by servo drives. This not only results in maximum acceleration, but also ensures maximum accuracy and exceptional reliability of the injection processes, as well as high-precision speed, position, and pressure control.

Aftermarket Solutions

Milacron's aftermarket solutions bring you the industry's most extensive line-up of technology and service to help you get the most from your plastics processing equipment. From OEM parts and technical support to rebuilding/repurposing older plastic processing equipment, Milacron provides you with the widest range of tools and resources required to improve your processes and your bottom line.

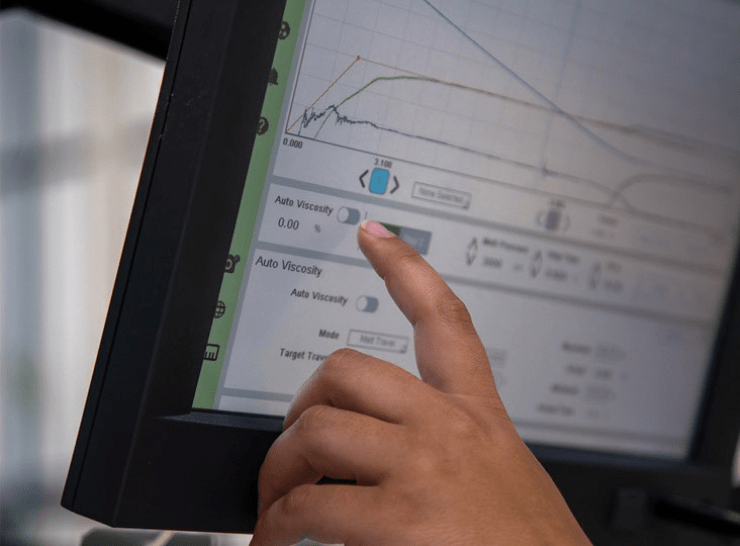

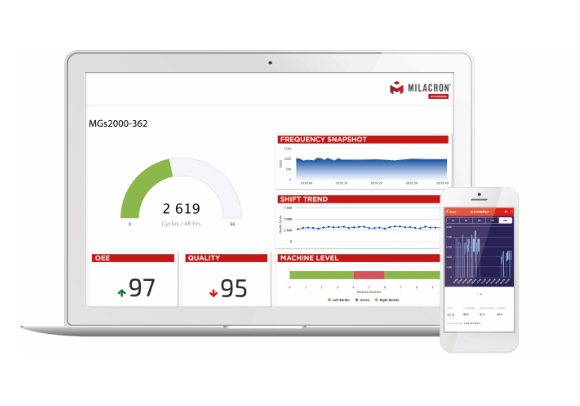

M-Powered

M-Powered is a portfolio of easy-to-use observational, analytical and support services that provides a competitive advantage through insight. Leveraging Internet of Things (IoT) technology, M-Powered provides unique intelligence on your current operations and future needs, sharpens manufacturing quality and productivity, and optimizes uptime.

M-Powered takes our entire suite of services to the next level of customer performance. M-Powered connects parts, service, rebuilds, retrofit and preventative maintenance services to our customers’ machines to provide a unified, stronger, optimized uptime.

Rebuild & Retrofit

As your business needs to change, your equipment needs to change too. Whether you need to retrofit current equipment to adjust to different outputs or a complete rebuild of aging equipment that still has life, Milacron can service your injection, extrusion and auxiliary needs.

Milacron’s Technical Service Team partners with you to review your new requirements, evaluate processes, and offer upgrade and rebuild ideas to keep your equipment running. Together we improve your equipment efficiency and increase productivity and uptime to help you achieve your output goals.

Milacron also offers training on the upgraded equipment for your company as well as parts and service programs to keep your machines working at peak performance.

Spare Parts

We know you’ve invested in the best plastics processing machines in the world so we’re invested in providing you with the best service to keep them running. With the largest inventory in the industry, fast delivery and competitive prices, Milacron is the only source you need for of injection, extrusion and blow molding aftermarket parts.

Our goals and commitment to our customers are to:

Maintain global stock levels to have your most used parts and consumables in stock every time

Ship all parts the same day ordered

Continuously Invest in Screw and Barrels

Contact Milacron

CONTACT US

General information: info@milacron.com

Vertretungsberechtigter Geschäftsführer

Executive officer: Winfried Stöcklin

Registergericht

Freiburg HRB 260914

VAT No. 05077/04310

VAT ID No.DE113538319

* Indicates required field

"*" indicates required fields